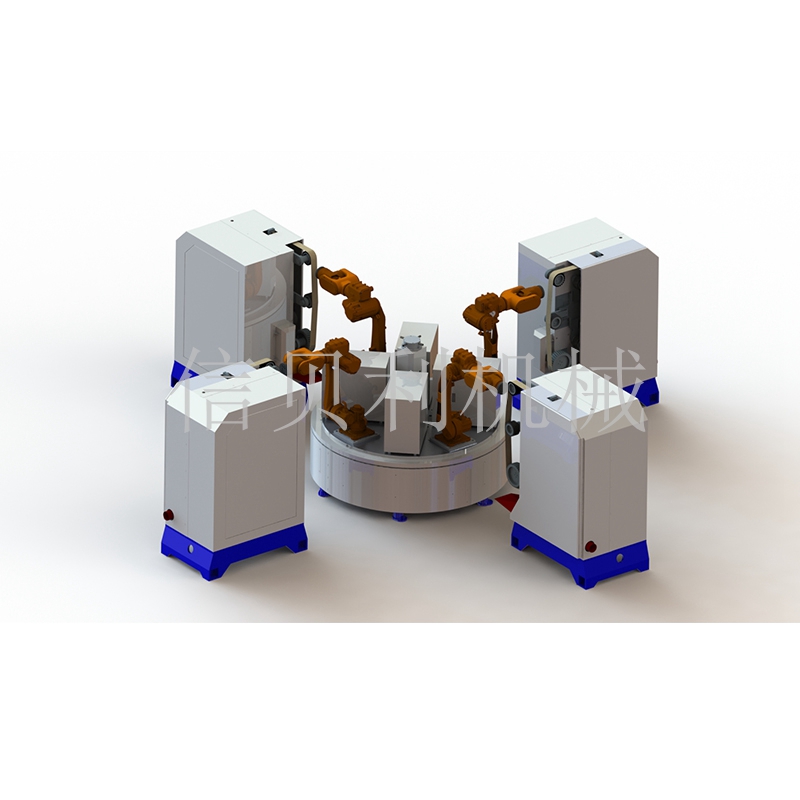

Equipment area: 5800*5800*2000mm;

Total weight of equipment: about 6500kg;

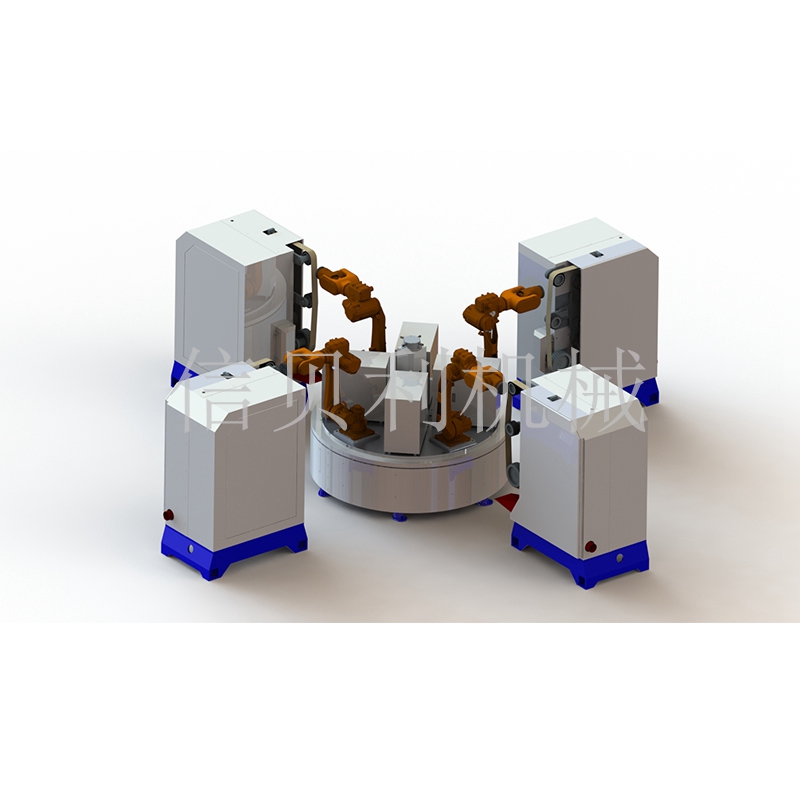

Motor specifications: disc revolution motor: 2.2KW; column main motor: 5.5KW; column front and rear motor: 0.75KW;

40kg robot power: about 6KW;

Disc diameter 1.8 meters, 40kg robot *4;

M20 column *4;

Rubber wheel specifications: diameter ?100-?350mm; width 1′′-3′′;

Consumables specifications: length 162", width 1"-3";

Applicable consumables: abrasive belt, silencer wheel.

Working line speed: 20m/s;

The manipulator disc and the M20 sanding belt column are controlled by a fully automatic servo operating system. Each robot can go through four processes to achieve different fineness processing;

M20 sand belt column can automatically adjust the contact depth between the belt and the workpiece to ensure the processing effect;

M20 sand belt column can automatically correct the belt offset;

Four robots are placed on the disc to greatly reduce the efficiency of the equipment when the space is greatly reduced;

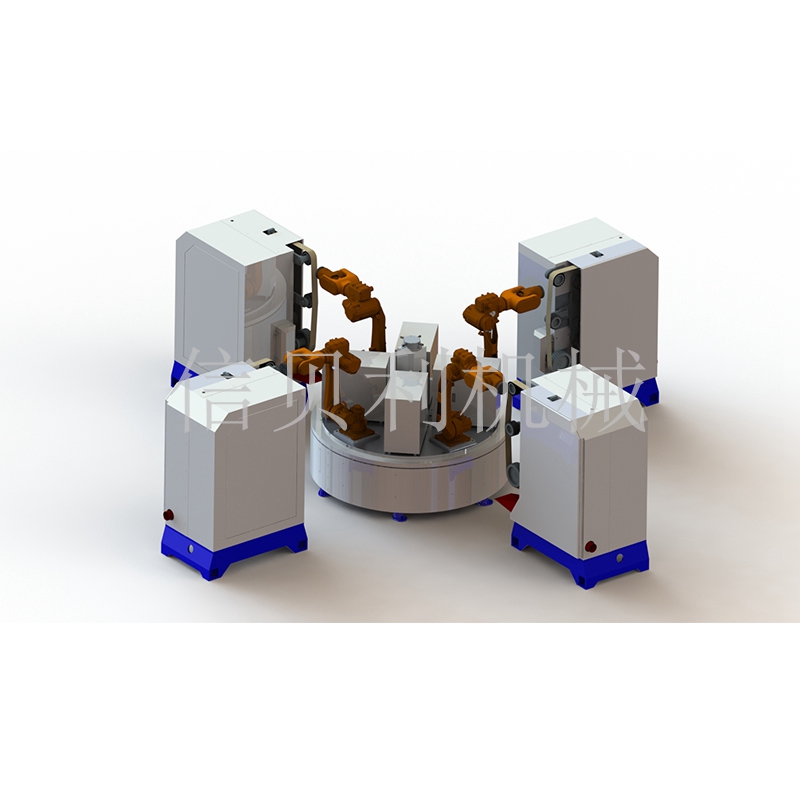

It can be processed by different parts of the rubber wheel or different rubber wheels according to different workpiece requirements, or it can be profiled on the rubber wheel; it can process plane, arc surface, seam position, etc.

Applicable to all kinds of medium and high-volume bathroom hardware with different shapes and multiple curved surfaces.